Licensed Contractor For Your Renos

July 22, 2013

Have you ever tried a do-it-yourself project? I’m not talking about making jewelry out of paper clips or clothes out of recycled cereal boxes, I’m talking about fixed something old or broken in your home that requires a visit to those aisles in Home Depot where no one but a contractor would feel comfortable. One would think that a carpenter would have an easy time of completing a couple of DIY projects in his own home, but the reality is, sometimes, things just don’t come together as planned. Sure, we have the expertise and the tools to get just about any home renovation done, but as Jeff Goldblum is often quoted in Jurassic Park, “Life finds a way.” Here’s my experience on how DIY projects can go wrong, even if everything looks like it’ll go right.

It’s no secret that the big joke among carpenter’s wives is that repairs take forever to get done at home. The same holds true for Robert and I. After a long day of work, we want nothing more than to “not fix stuff” and quite often, the expression “I’ll do it tomorrow, dear” gets us in heaps of trouble. Well, my DIY project started with some “extra” materials from a job. We were doing a full kitchen renovation at my sister’s home, stripping the kitchen down to the drywall and framing, and changing the layout of the kitchen. Work there was going slow. At first, a lot of the work was getting done by Robert over the weekends, but I came on board to help finish the kitchen after we had a couple of our other projects wrapped up (As a side note, if you ever want to save a ton of money on your kitchen, doing the work yourself is a great way, as long as you like working weekends and evenings).

As I was pinning on the last piece of baseboard and Robert was packing up the last of the hand tools, we felt that sense of relief and excitement a contractor gets when a job is completed. Then we noticed “the box”. My sister had purchased a wire cabinet shelf system and the box for it was mocking us from the corner of the room. You know, one of those things when you open a cabinet and pull out a shelf and voila! You can reach things easily in your cabinet without having to get on your hands and knees to discover the 8 years old bag of cookies hiding at the very back. This one was an off the shelf product from Lowes, and it meant that I would be installing it. Robert figures that part of my education as an apprentice is deciphering the instructions most likely written in a foreign language and then attempting to install it without using the recommended tools.

I hate putting together hardware that requires instructions. Give me a pile of lumber and a saw instead, and ask me to build a replica of the CN Tower and I’m happy. Hardware requiring multiple screwdrivers and a variety pack of screws in little plastic baggies makes me think these manufacturers have an agenda that involves me scratching my head and becoming frustrated. I hate being frustrated.

But wait. My sister tells us that she doesn’t think that she’ll need a pull out shelf in her cabinet. Hooray! I’m saved. The pull out shelf is going back to the store where someone else will take it home and wonder which side is up on the installation manual.

But wait.

My sister utters the words that I know will have far reaching repercussions. She says, “Hey dad. Instead of taking this back, do you think that mom would like this installed at your place?”

At that moment, I felt like Alan Rickman at the end of Die Hard as he is falling off the side of the building, mouthing the word, Nooooooooo! Of course Robert would think this is a swell idea. He would also think it’s a really swell idea to have me install it. Secretly, I think my sister is punishing me for that time I put her barbie doll in the garburator.

A couple of days later, I arrived at the office (which, coincidentally, is my parents home) with a cup of coffee in my hand only to discover that “the box” had managed to sneak its way into the kitchen, where Robert and I usually have our quick morning meeting before we head to our desks or head out the door. “Guess what you’re doing today, Michael,” said Robert. “Helping you install that shelf thingy?” I asked. “Nope. You get that honour all by yourself. I’m off. I have an appointment.” And with that, he put on his shoes and walked out the front door.

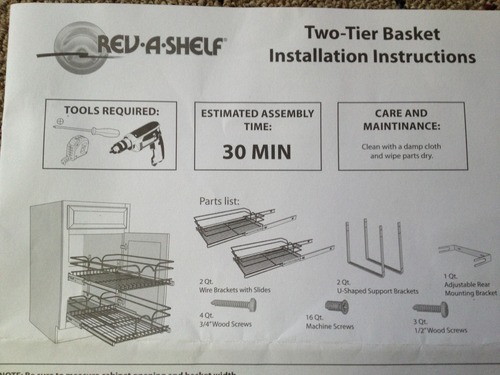

I grabbed my utility knife and carefully open the box. Luckily, the instructions were right on top. I must say that I love it when you don’t have to pull everything out of the box in order to get at the instructions. Looking at the instructions, I immediately spotted something that I know, without a doubt, is a lie. In big letters surrounded by a border, it says, “Estimated Assembly Time: 30 min.” I want to know how they came to that conclusion. Did someone sit there with a stop watch, yell “GO!”, and start putting this thing together? Was this person someone they dragged off the street or were they professional shelf installers? Did they take into account that, as a carpenter, I’m required by law to take a coffee break? That doesn’t leave a lot of time for the actual install.

Surprisingly, the directions were fairly straightforward. My confidence in getting the shelf in place in a reasonable amount of time was pretty high. Then I grabbed one of the U-shaped support brackets and place it in the cabinet. Hmm. It appeared that the shelving system was about 1 inch too short on either side of the inside of the cabinet. My confidence at getting it done quickly wavered a little, but I though, “Easy enough.” As a contractor, we have a lot of leftover material from other jobs, and I could simply go out into the garage and rip down some plywood strips, pin them to the inside of the cabinet, and attach the bracket to the plywood strips. I got up, took two steps, and stopped.

The table saw for cutting plywood was at my sister’s garage, all the way across the city. So were the brad nailer and air compressor. We had left them there because we needed the room in our vehicle to pick up some materials for our next job. The plywood was in the garage at my place, a few blocks away. I dialled Robert. “Uhhh…hey. The shelf thingy doesn’t quite fit. I’ll need to add some plywood. I’m heading to Jackie’s house to pick up our tools too. Huh? Yeah, well, I need those tools to install the shelf. Yes. I read the directions very carefully. Yes. I’m sure that I know how to install this thing. No. I’m not lying. Okay. I’ll see you later.”

After stopping at my sister’s to pick up our tools, grabbing a donair, and then stopping at my place to pick up the plywood, the installation time was up to 2 ½ hours, and I still didn’t have the shelf out of the box. I finished ripping some ¾ inch and ¼ inch plywood, setting up the brad nailer and compressor, and grabbing the hand tools needed to install this sucker. Now, I was in my element. With my brad nailer in hand, I pinned the plywood strips strategically to the inside of the cabinet, Ca-chunk! Ca-chunk! Ca-chunk! Now, the only thing left to do is screw the shelf unit to the strips of plywood.

12 screw holes, 7 screws. I swear it’s a conspiracy to sell more hardware and fasteners. In addition, the screw holes will easily accommodate #6 screws, but we only have #8 and bigger. How did I learn this? The hard way of course. When you break off one screw head, sometimes you just think that the screw was a dud. Break two in a row, and you’re doing something wrong. So off to the van to grab a drill bit to make the screw holes a little larger. With the final screw in place, I packed up all of the tools, and surveyed my handiwork. My estimated 30 minutes now should at about 3 ½ hours. What a great waste of a morning.

So, what’s the point of this story, you ask? Well, I guess there are three points. The first is that in doing renovations, sometimes things don’t work out quite the way we want them to. As contractors, even when we’re doing our own projects, things can take more time, require more materials or just plain not go well. This can happen on your project too. As much as we try to avoid the unexpected, we have to remember to plan for it as well. My second point is if you plan on going the DIY route, be sure you know what you’re getting into. Putting in that shelf was no big deal for me, because I had the extra tools available and the experience to know how to correct a problem, but the average DIYer might not own these tools and might not be prepared for things outside of the instruction manual. The advice from the staff at Home Depot will only get you so far. And finally, if it makes sense, get someone else to do it for you. After all, why stress yourself over ¾ inch plywood and 5 missing screws?

If you’re in the Greater Edmonton area and are looking for a contractor for you renovation project, visit our website at www.nordalta.com/contact/ to find information on how to contact us. We’d be happy to speak to you about what we can do to get the ball rolling on your next home or office project. You can also leave comments with us at robert@nordalta.com.

Michael Breault is a project coordinator for Nord Alta Construction. You can find the company website at www.nordalta.com. You can also find Michael and Nord Atla Construction on facebook at www.facebook.com/NordAltaConstruction, on twitter at www.twitter.com/Nordalta, and on LinkedIn.

Robert Breault is the president and owner of Nord Alta Construction. You can find the company website at www.nordalta.com. You can also find Robert and Nord Alta Construction on facebook at www.facebook.com/NordAltaContruction and on LinkedIn.